REAR SUSPENSIONS OF THE 4CV,

DAUPHINE, R8-10 AND DERIVATIVThe road holding of these vehicles is determined by the rear suspension layout and condition. The essential suspension concept is of two swinging arms articulated on the gearbox. Two areas of wear develop, with cumulative effects, and are often found in registration mechanical inspections of these swing-arm rear suspensions:

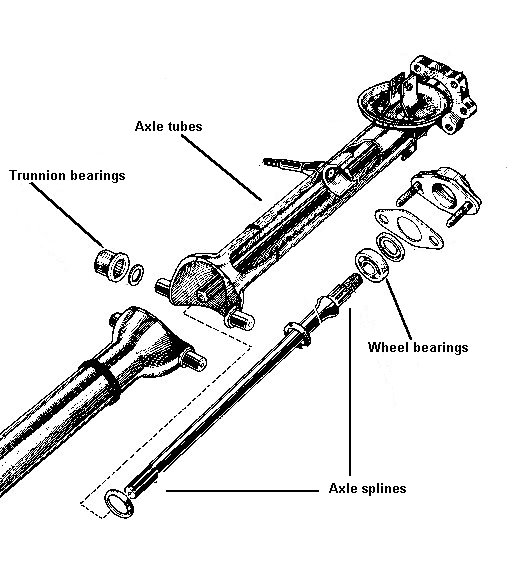

A - Wheel bearing play :

The wheel bearing simply runs on a ball race encased in the lateral constraints of the rear suspension hub. Take a moment to imagine the loads supported by the ball bearings in contact on some millimetres of the crown support of the bearing, when the vehicle takes a corner enthusiastically! We do not need to think of the stresses on an R8G: the bearing is the same for a 4CV, Dauphine and R8/R10.

This shortcoming has been corrected on modern vehicles (as it was already on the front suspension of our vehicles) by the fitting of double opposed conical bearings, which absorb elevated lateral loadings.

Even a new bearing posseses a slight play. An axle is not properly supported if it is able to 'navigate' by articulating some hundredths of a millimetre on the bearing and if it is poorly held at the universal joint end. This provokes a perceptible play at the wheel. The universals must not have play of course, but what is the most important is that the play on the part of the axle shaft chanelled into the slide of the universal must be as little as possible.

Let us be clear that it is impossible to achieve a 'no play' result! Even on new vehicles, there was play in the location of the axle shaft, leading to a play at the rim of about 1mm. You could not do better. (It would be possible in theory, by modifying the inside of the axle tubes and by adding another bearing near the universal).

To minimise the play of the bearing, three important points:

- Assure yourself that the axle shaft has a minimum play where it fits into its universal (test carried out without grease). Optimise the universal and the shaft.

- Confirm that the universals have no play and that any play is not arising from the part leading into the transaxle.

- Mount new wheel bearings (these are standard components, it does not matter what make).

B - The rear axle outer swinging arms :

These are articulated on the transaxle in the vertical plane, in relation to the vehicle, and are (supposedly) held fixed in the fore/aft plane. This articulation is through two steel trunnions turning in caged needle roller bearings, which are fixed solidly in support mountings making part of the transaxle. In the horizontal plane, all the unevenness of the road (holes, bumps, small obstacles) is taken laterally by the caged needle bearings, with a levering effect equal to the length of the axle tube.

Unfortunately, it was necessary to wait until the R8 for tie rods limiting the loads in the horizontal plane. Some 4CVs and Dauphines received tie rods as accessories, but those did not function in the axis of articulation and the remedy was often worse than the complaint.

On a new vehicle, no play existed. After a distance, which depended on the style of driving and on the type of road, the needle rollers wore the bearing case. This provoked an insidious play which was masked by the compression of the suspension springs. This play was cumulative with the wheel bearing play. No wonder crosswinds affected these vehicles and influenced the heading of the car.

To minimise the play in the axle tube, some solutions :

- Mount trunnion bearings made from nylon or teflon. The play is removed and allows the vehicle to pass registration tests. In less than 1000 km, the trunnions will wear the nylon or teflon bearing, and all must recommence. Bearings made from bronze hold up a little better, but the same causes produce the same effects……

- Mount new needle roller cages for the trunnion bearings. They are practically impossible to find now. Five years ago, they were again referenced at ALPINE!

- Recondition the cages. It is necessary to note that the wear areas on the cages and needles are always the same (4 to each side). Dismantle a dozen old cages, measure the wear in the needles, choose the largest size and remount the cages, having care to orient the traces of the old fitting in the part of the cage of the vertical plane. It works excellently!

- Take note, that is not always enough. It is also necessary that the trunnions must be unmarked! They become "corrugated" with wear. If they are damaged, the bearings stay in the one place in the corrugations and the play reappears. There is no solution other than to find some axle tubes on which the trunnions are not marked. You will not find new ones even in swap meets! It is necessary to search! Repairing the trunnions is not possible, for no machining shop will put such an unbalanced mass on a lathe. In the factory, the axle tubes were made in three parts, then assembled by welding.

Jean-Pierre Delaunoy (Translated from web-page 2001)

From personal experience, I can also point to another area of wear and resultant play - movement of the rear wheel centre with brake drum on the splined outer end of the rear axle shaft. This appears to be a result of the wheel being incorrectly or inadequately tightened onto the shaft by the tapered washer at the axle nut. If the wear and play is bad, it may be necessary to replace both the wheel centre and the axle.

English translation and adaptation from George COOK of RENAULT 4CV REGISTER OF AUSTRALIA